Thermoelectric & ALD

Research & Discoveries

Highlights

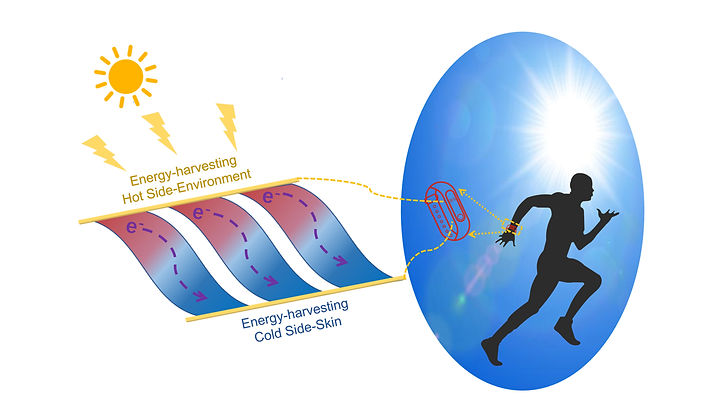

Flexible Amorphous Thermoelectric Materials

April 20, 2020

Most crystalline inorganic materials, except for metals and some layer materials, exhibit bad flexibility because of strong ionic or covalent bonds, while amorphous materials usually display poor electrical properties due to structural disorders. Here, we report the simultaneous realization of extraordinary room temperature flexibility and thermoelectric performance in Ag2Te1–xSx–based materials through amorphization. The coexistence of amorphous main phase and crystallites results in exceptional flexibility and ultralow lattice thermal conductivity. Furthermore, the flexible Ag2Te0.6S0.4 glass exhibits a degenerate semiconductor behavior with a room temperature Hall mobility of ~750 cm2 V−1 s−1 at a carrier concentration of 8.6 × 10^18 cm−3, which is at least an order of magnitude higher than other amorphous materials, leading to a thermoelectric power factor also an order of magnitude higher than the best amorphous thermoelectric materials known. The in-plane prototype uni-leg thermoelectric generator made from this material demonstrates its potential for a flexible thermoelectric device.

Seeking High Thermoelectric Performance Materials with High-throughput Methods

April 1, 2021

High-throughput (HTP) experiments play key roles in accelerating the discovery of advanced materials, but the HTP preparation and characterization, especially for bulk samples, are extremely difficult. In this work, we developed a novel and general strategy for HTP screening of high-performance bulk thermoelectric materials. The performed full-chain HTP experiments cover rapid synthesis of the bulk sample with quasi-continuous composition, microarea phase identification and structure analysis, and measurement of the spatial distribution of the sample composition, electrical and thermal transport properties. According to our experiments, bulk Bi2−xSbxTe3 (x = 1−2) and Bi2Te3−xSex (x = 0−1.5) samples with quasi-continuous compositions have been rapidly fabricated by this HTP method. The target thermoelectric materials with the best Sb/Bi and Te/Se ratios are successfully screened out based on subsequent HTP characterization results, demonstrating that this HTP technique is effective in speeding up the exploration of novel high-performance thermoelectric materials.

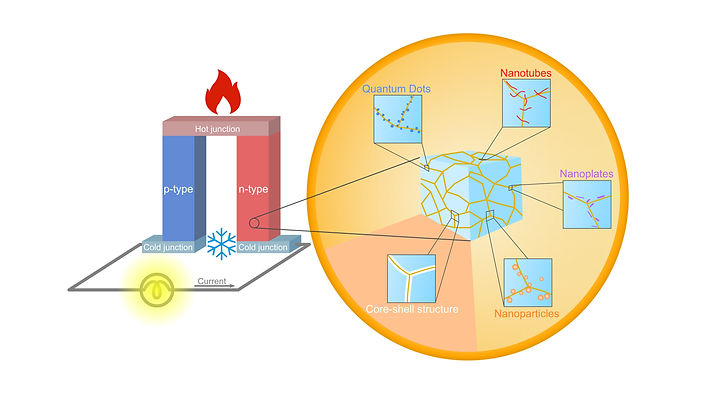

Interface/Surface Modification of Thermoelectric Materials

August 16, 2021

Thermoelectric (TE) materials are prominent candidates for energy converting applications due to their excellent performance and reliability. Extensive efforts for improving their efficiency in single-/multi-phase composites comprising nano/micro-scale second phases are being made. The artificial decoration of second phases into the thermoelectric matrix in multi-phase composites, which is distinguished from the second-phase precipitation occurring during the thermally equilibrated synthesis of TE materials, can effectively enhance their performance. Theoretically, the interfacial manipulation of phase boundaries can be extended to a wide range of materials. High interface densities decrease thermal conductivity when nano/micro-scale grain boundaries are obtained and certain electronic structure modifications may increase the power factor of TE materials. Based on the distribution of second phases on the interface boundaries, the strategies can be divided into discontinuous and continuous interfacial modifications. The discontinuous interfacial modifications section in this review discusses five parts chosen according to their dispersion forms, including metals, oxides, semiconductors, carbonic compounds, and MXenes. Alternatively, gas- and solution-phase process techniques are adopted for realizing continuous surface changes, like the core–shell structure. This review offers a detailed analysis of the current state-of-the-art in the field, while identifying possibilities and obstacles for improving the performance of TE materials.